Traccia

Developed by: IRSA informatica

For food production companies subject to EEC Regulation no. 178 of 28/01/2002, a flexible and simple tool for managing batch production and documenting, as required by law in force, the origin of the ingredients used and the destination of the finished product.

Traccia is a program dedicated to companies that make food production, and who need to track the product, starting from the ingredients used up to the sale.

The program operates in close connection with the management system used in the company, from which it draws information relating to raw materials, the articles being produced, suppliers, customers and finally the sales documents with which the traceability of the products is exhausted.

The operating modes are very simple, and are briefly illustrated below.

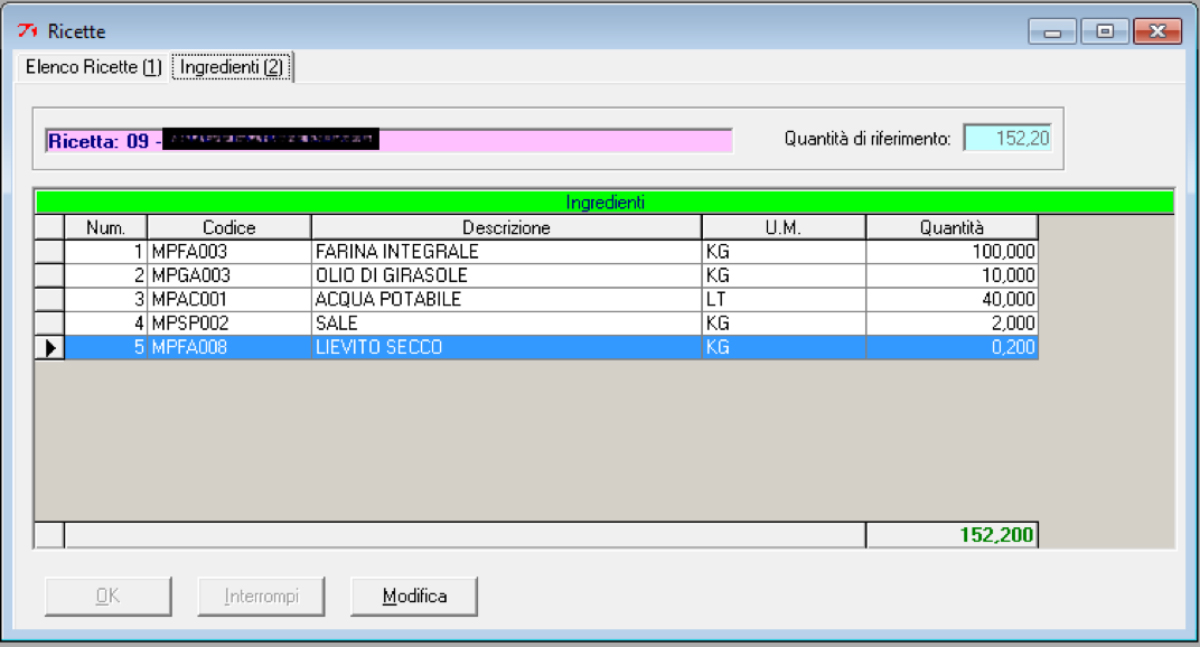

The recipes

The starting point is the recipe, consisting of a list of components, with relative quantities (doses). The recipes can be entered with reference to a quantity of product as desired. The doses will then be proportionate to the quantity to be produced at the time of each production.

Packaging list

The recipes identify the ingredients for the production of the finished products. Each finished product is associated with a recipe. However, in the finished product, in addition to the ingredients, there will be other components that determine the packaging of the product and that are generically identified as "packaging".

With a special mask called "Packing List" it is possible to define the items used for packaging for finished products.

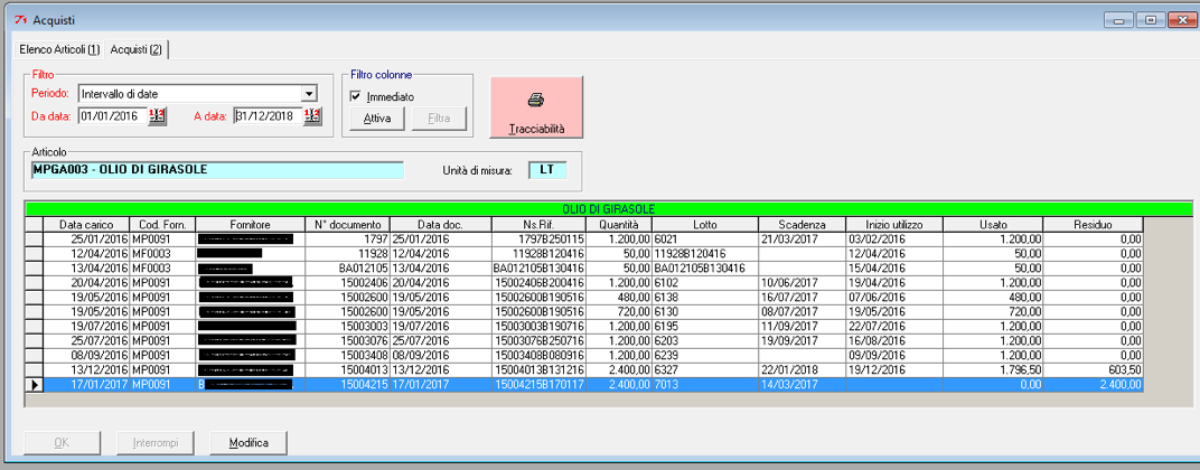

Purchase lots

For the raw materials used in production, purchase lots must be recorded.

The recording of raw material purchases is extremely simple and reduced to the essential data (supplier, reference to the purchase document, quantity, and obviously batch and product expiry.

The program will keep track of the quantity used for each lot until it runs out.

Among the raw materials for which the purchase lots must be registered, in addition to the ingredients of the recipes, there will obviously also be lots relating to the packaging necessary for the packaging of the products.

With a "Traceability" button the program will always be able to show the productions in which a certain batch of an ingredient has been used, and also the sales relating to these productions.

As will be seen later, it is possible to use the program in a mode called "automatic batch consumption". In fact, after the program has started consuming a lot of a given item, the program will assume that same batch as the default batch in all subsequent productions, until it runs out. Once a lot has been used up, it will start to consume the next lot, that is, the one with the closest expiration date among those not yet used. This automation can greatly facilitate the management of traceability, provided that the criterion of starting the use of a new batch only after exhaustion of the previous one is strictly respected, and always proceed with batches in order of expiry date.

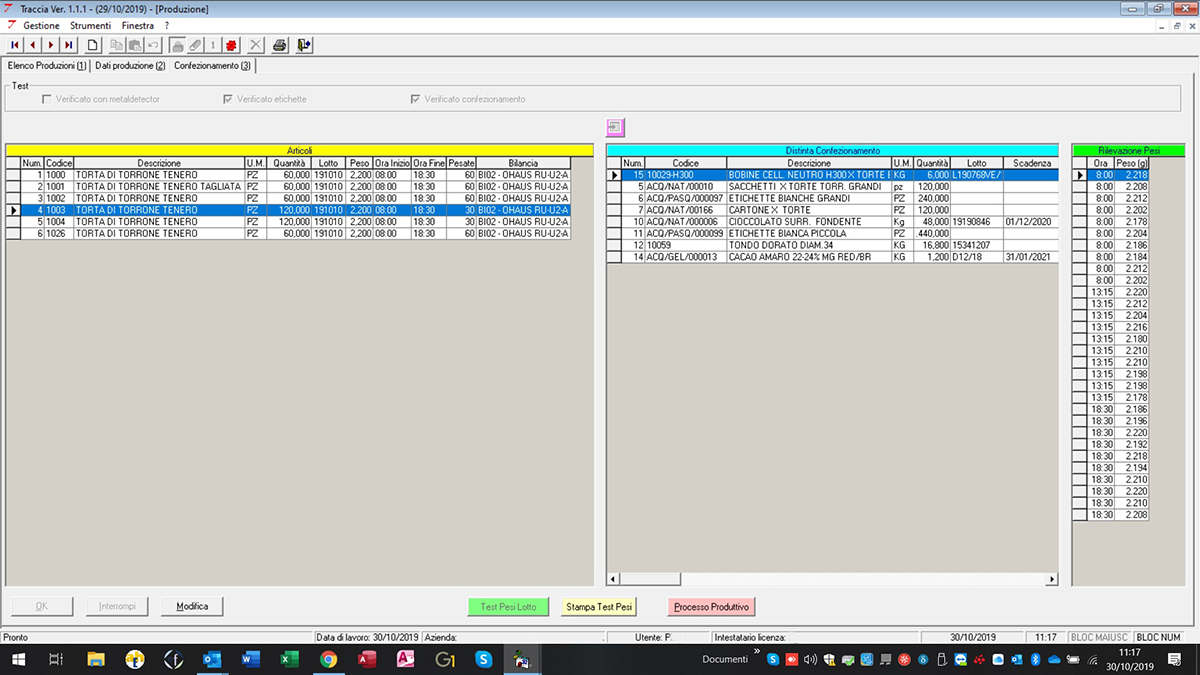

Production management

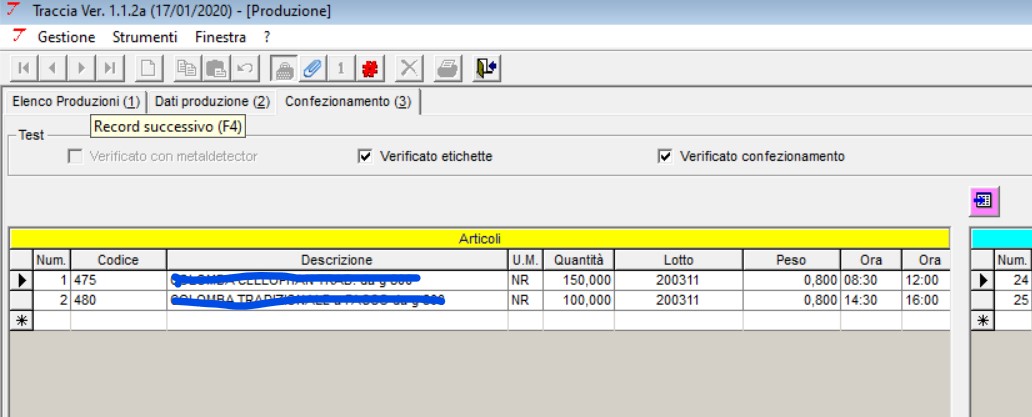

For each production, a new registration must be created with the data relating to it: identification (production number), production date, description.

The recipe used and the quantity produced will then be indicated. The program automatically calculates the ingredients used with their respective quantities, based on what is defined in the recipe. It also identifies the batch used for each ingredient, based on the set "automatic consumption" criterion.

The production batch and its expiry date must also be indicated.

A "Traceability" button allows you to print the production traceability, which will include the list of batches of the ingredients used with references to the related purchase documents (upstream traceability), and the list of sales made for that batch, with reference to the customer, document number and type, quantity, etc. (downstream traceability)

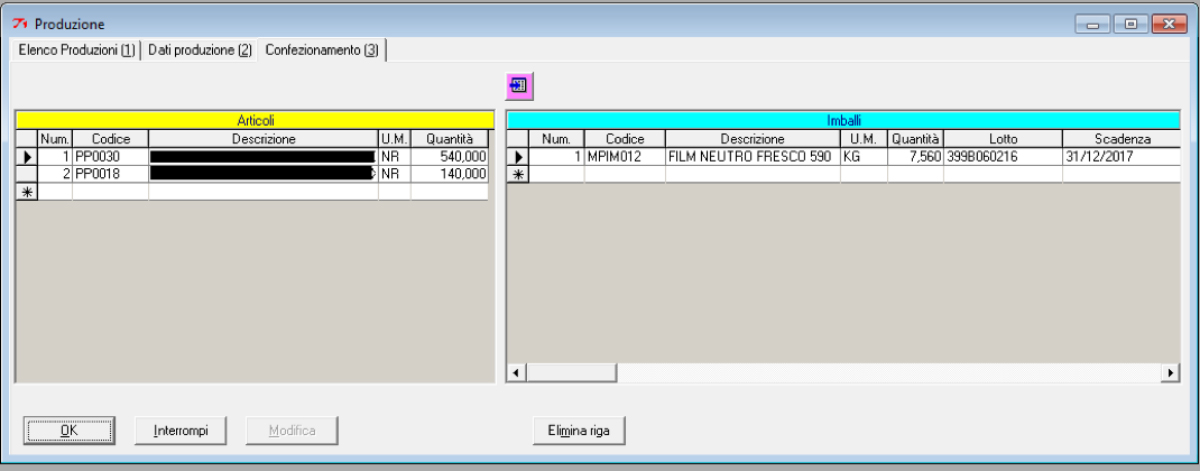

Packing

For each production we will indicate the items (finished products) that have been obtained and for each of these the list of packaging used (this information is detected by the program from the Packaging List, if present).

A series of tests carried out on the production of the belonging lot can be inserted in the packaging window.

Additional features

In addition to those illustrated, which constitute the basic functions of the program as inherent to the management of product traceability, there are several additional functions available which support the activity that a production company in the food sector must carry out.

These include:

Production programmation

Weed detection

Sanitation interventions

Management of control cards

Package weight management

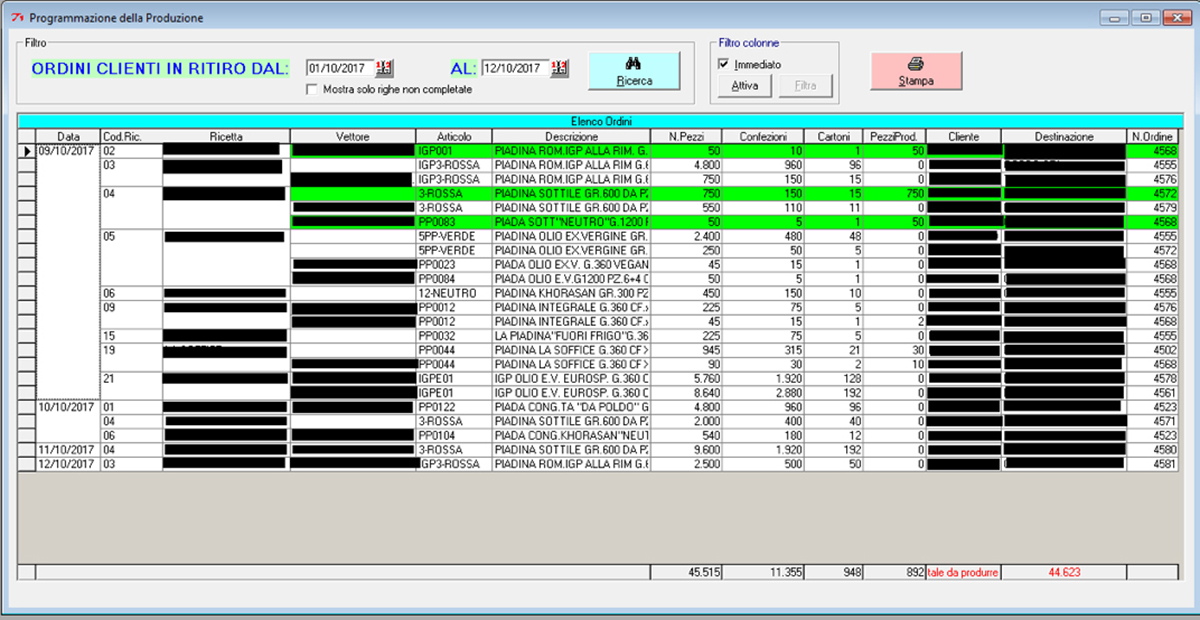

Production programmation

This function is intended to be an aid for the Production Manager in his daily production planning activity.

In fact, the program briefly presents the list of items ordered by customers on the screen (information acquired from the management program), grouped by date of collection by the courier and by recipe, and with the quantities ordered.

This allows the Manager to schedule the production having an immediate and updated view in real time of the orders present and the delivery time.

Weed detection

In a food production company it is important, and a requirement required by Quality management, to keep under control and document the presence of pests (cockroaches, flies, rodents, etc.) caught through special traps.

The program offers a tool that helps in this pest detection activity.

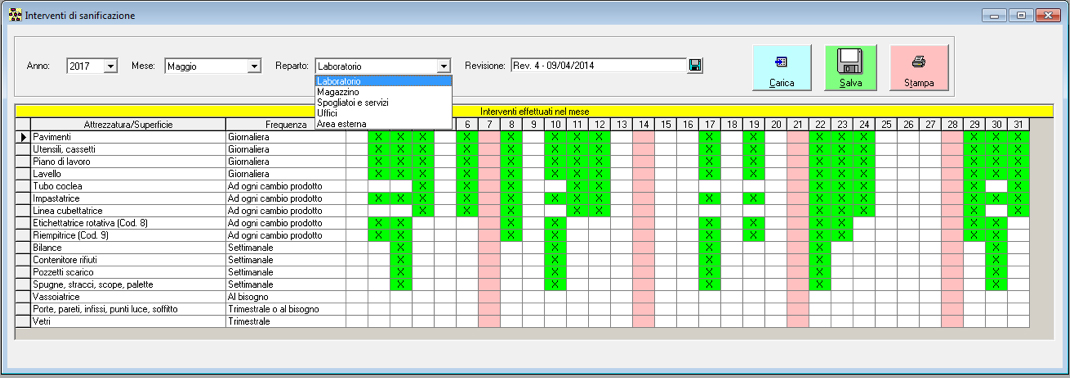

Sanitation interventions

Another activity required of a food production company is the documentation of the cleaning and sanitizing interventions of the various environments, in particular as regards laboratories and warehouses.

A valid help in this documentation activity, requested by health control and certification bodies, is given to this function present in the traceability program.

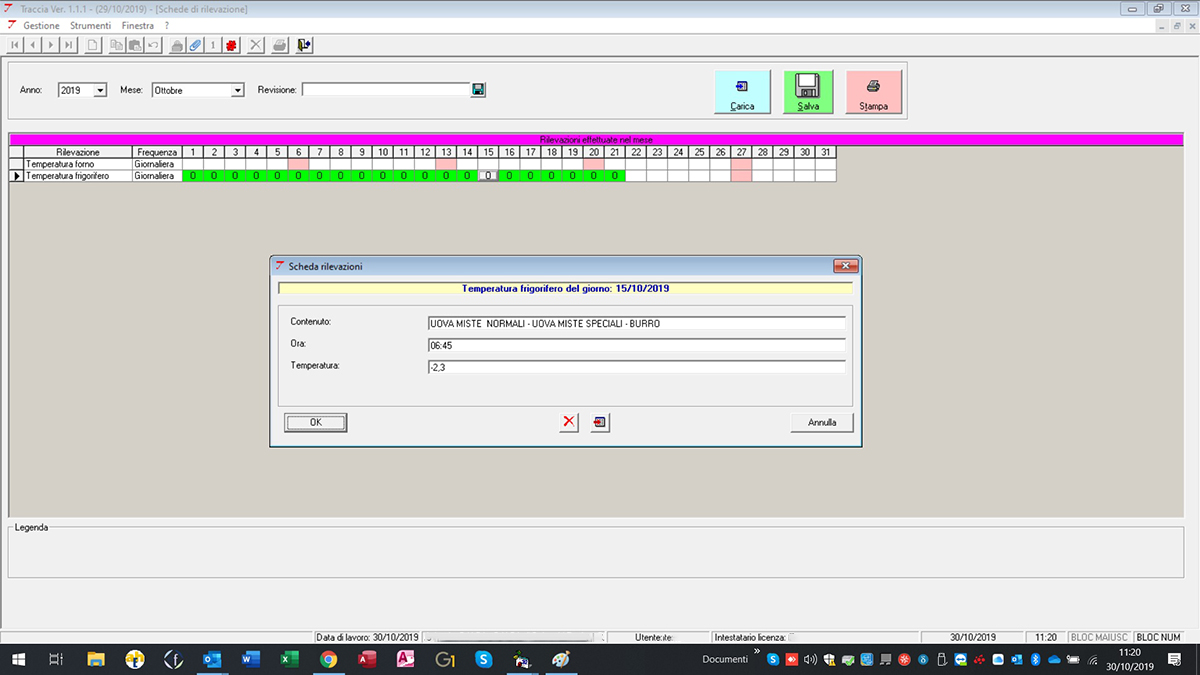

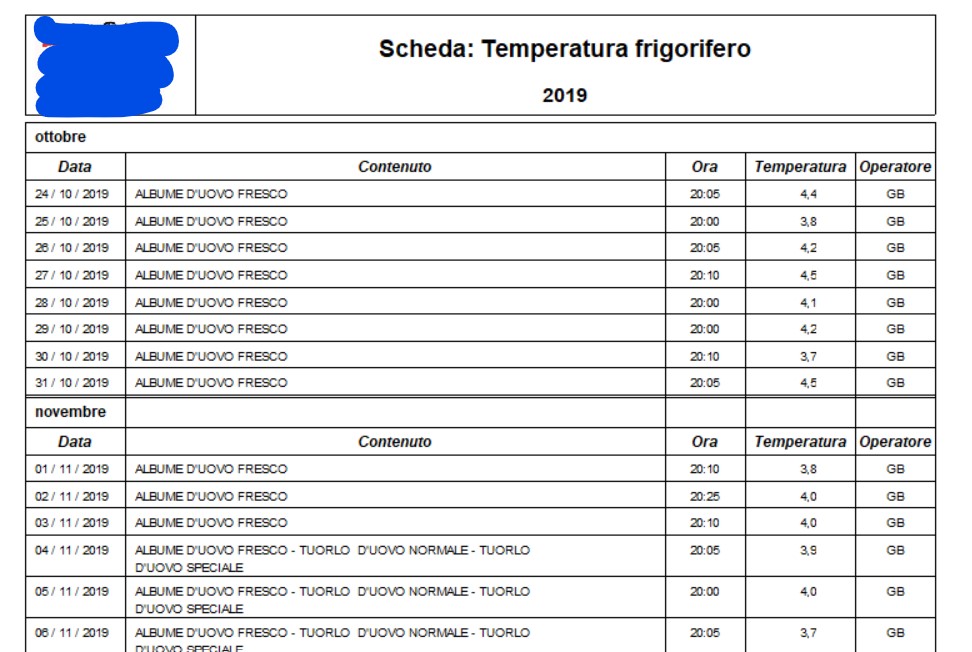

Management of control cards

It is an open control management system to be carried out for equipment or processes that allows to store and check the data collected.

Based on a specific range within which the check is considered passed and a predefined periodicity, it checks that the readings are performed correctly.

For each type of detection there is the relative printout, where the results of the readings are reported.

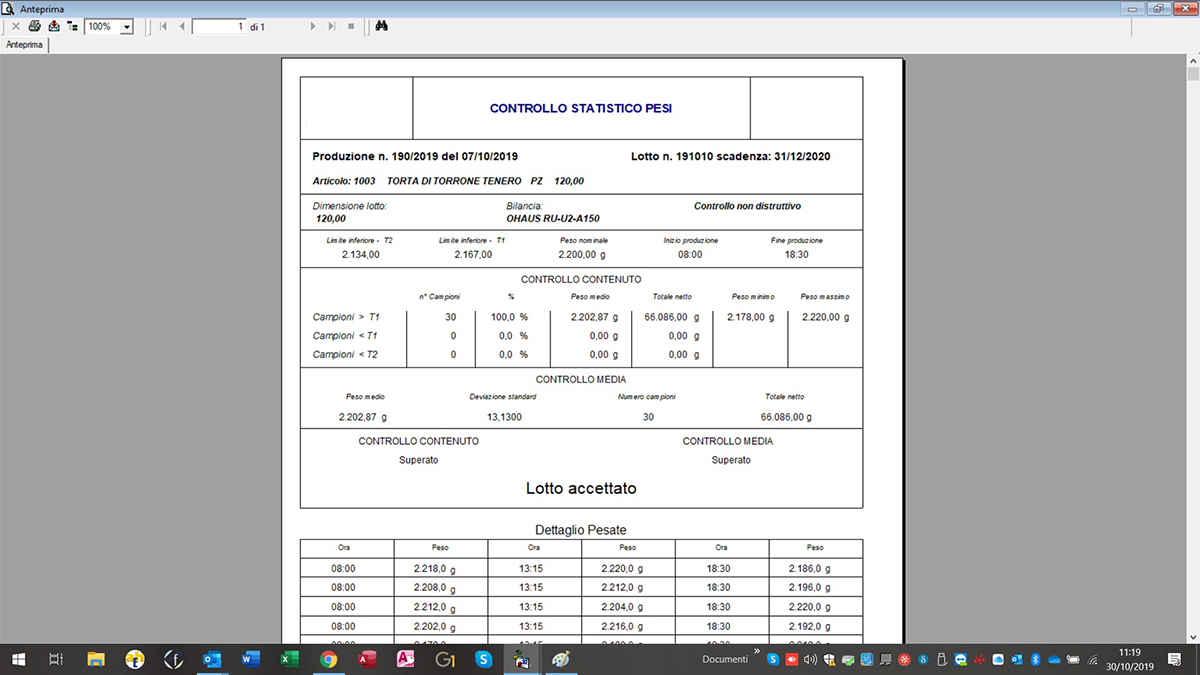

Package weight management

Another activity required from a food production company is the documentation on the weighs performed on the packages.

A valuable aid in this documentation activity, requested by regulatory compliance control bodies in the calculation of the average weights. A series of internal functions calculates the number of weighs to be performed by law and verifies the certifiability of the average, so that the estimate symbol can be affixed on the packages.

As with all control and certification functions, the results are printable with reports built to meet the reference standards.